Oil Removal

The oil and grease discharged from industries like petrochemicals, food and beverage, etc., has become an ever-growing concern for both solid waste facility  operators and wastewater treatment plants. These are often not properly treated and hence they build up in the sewer systems constricting flow, which can even cause sewer back-ups into homes and overflow discharges onto streets. operators and wastewater treatment plants. These are often not properly treated and hence they build up in the sewer systems constricting flow, which can even cause sewer back-ups into homes and overflow discharges onto streets.

In general, grease can be categorized into two major types – brown grease and yellow grease. Brown grease is basically floatable fat, oil, grease and settled solids recovered from grease control devices which are not reusable and are disposed off through water treatment facilities. Yellow grease, commonly referred to as recyclable FOG, is uncontaminated oil, grease and fats.

Treatment

The basic processes used to treat oil and grease in wastewater involves recovery of valuable oils and the removal of undesirable pollutants before discharging to a receiving system. The techniques to be used depends mainly on the type of the oil-water mixture, i.e if the mixture is oil and grease present as free oil, dispersed oil, emulsified oil or dissolved oil.

Most of the oils can be separated from water surfaces simply by employing skimming devices. A cost efficient yet dependable way of water treatment, these skimming devices can very efficiently remove oil, grease and other hydrocarbons from water. Skimmers are specially employed before using membrane filters as they prevent filters from blinding prematurely and keep chemical costs down because there is less oil to process.

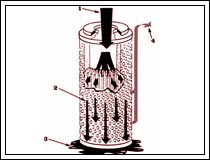

Wastewater from oil refineries, petrochemical plants, chemical plants, and natural gas processing plants contain such huge amounts of oil and suspended solid that cannot be treated by skimming alone. In such cases, a oil water separator is used to separate the oil and suspended solids from their wastewater effluents. A oil-water separator is a device used to remove the oil from the waste stream water while allowing the rest of the water collection system by gravity. Wastewater from oil refineries, petrochemical plants, chemical plants, and natural gas processing plants contain such huge amounts of oil and suspended solid that cannot be treated by skimming alone. In such cases, a oil water separator is used to separate the oil and suspended solids from their wastewater effluents. A oil-water separator is a device used to remove the oil from the waste stream water while allowing the rest of the water collection system by gravity.

Typical oil-water separators are fabricated by using Stroke's Law to define the rise velocity of oil droplets based on their density and size. These devices, working on the specific gravity difference between the oil and water, make the suspended solids settle at the bottom of the separator as a sediment layer. The oil rises to top of the separator and the cleansed wastewater forms the middle layer between the oil layer and the solids. The water layer is then further treated by an Electroflotation module for additional removal of any residual oil and then is treated biologically for removal of undesirable dissolved chemical compounds.

|